In industrial and mobile installations, reel cables play a critical role in delivering power, control signals, or data to moving machinery. Unlike stationary cables, these cables are constantly wound and unwound during operation, placing them under mechanical stress that can quickly lead to failure if the design is not optimized.

High-cycle applications — environments where the cable experiences thousands or even millions of bending, twisting, and tensioning cycles — demand careful consideration of cable design, materials, and reel mechanisms. Failure to address these factors can result in downtime, costly repairs, and safety risks.

This article examines how reel cable design directly impacts performance in high-cycle environments. We explore materials, mechanical structures, insulation options, environmental considerations, and maintenance practices, providing guidance for engineers, technicians, and facility managers seeking reliable, long-lasting reel cable solutions.

High-cycle applications are characterized by repetitive movement and mechanical stress. Examples include:

Cranes and hoists: Frequent extension and retraction of power or control cables.

Automated production lines: Robotic arms and conveyor systems requiring flexible cable movement.

Construction and temporary installations: Mobile equipment and portable power distribution.

Entertainment and event setups: Repeated deployment and storage of lighting, audio, or broadcast cables.

In these scenarios, a cable must withstand bending, torsion, tension, abrasion, and environmental exposure while maintaining electrical integrity.

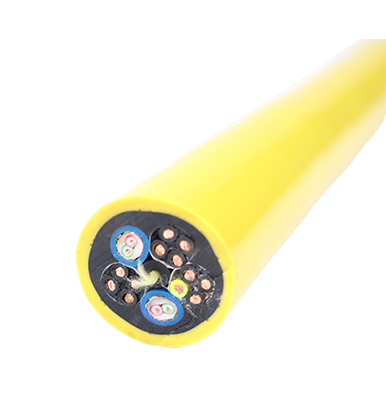

Reel cable performance begins with its construction. High-cycle cables are engineered with multiple layers to resist mechanical and environmental stresses.

Conductor

Fine-stranded copper or specialized alloys are used for flexibility and low electrical resistance. Stranding pattern affects bend life and torsional tolerance.

Insulation

Protects conductors from short circuits and mechanical damage. Common insulation materials include rubber, thermoplastic elastomers, polyurethane, and composite layers.

Filler and Core Stabilization

Maintains internal conductor spacing, reduces compression under tension, and ensures uniform bending behavior.

Shielding

Optional, depending on whether the cable carries data or control signals. Shields prevent electromagnetic interference (EMI) and maintain signal integrity in high-cycle motion.

Outer Jacket

Provides protection against abrasion, chemicals, UV radiation, moisture, and extreme temperatures. Materials may include PVC, polyurethane, rubber, or multi-layer composites.

High-cycle reel applications demand a cable that can flex thousands of times without degradation. Key design factors include:

Fine-stranded wires provide flexibility and reduce stress concentration.

Conductor diameter and stranding pattern determine the bending radius and fatigue resistance.

Specialized twisting reduces torsional strain during winding and unwinding.

Thicker insulation improves mechanical protection but can reduce flexibility.

Elastomeric or polyurethane insulations maintain elasticity under repeated cycles.

Multi-layer insulation balances flexibility, durability, and abrasion resistance.

Abrasion-resistant jackets reduce wear from contact with reel guides, pulleys, and industrial surfaces.

UV and chemical resistance extend cable life in outdoor or harsh industrial environments.

Braided or reinforced jackets enhance tensile strength while maintaining flexibility.

The design of both the cable and the reel influences high-cycle performance.

Every cable has a minimum bending radius, specified by the manufacturer.

Exceeding this radius increases conductor fatigue and insulation cracking.

Optimal reel diameter and guide rollers help maintain proper bend radius throughout operation.

Excessive tension during retraction or deployment can stretch conductors, weaken insulation, or damage connectors.

Controlled retraction mechanisms, such as spring or motorized reels, distribute forces evenly and reduce localized stress.

Torsion occurs when the cable twists along its axis during winding or unwinding.

Cable designs with concentric stranding or specialized layering resist twisting while maintaining flexibility.

Choosing the correct material for insulation and jackets is crucial for long-term performance.

Affordable and easy to handle.

Moderate flexibility and abrasion resistance.

Suitable for light-duty indoor or short-cycle use.

Highly flexible and resilient under repeated bending.

Resistant to compression, abrasion, and moderate temperature variations.

Heavier and more expensive than PVC.

Superior abrasion, oil, and chemical resistance.

Maintains flexibility under extreme temperature ranges.

Ideal for demanding outdoor or industrial applications.

Provides enhanced mechanical protection and tangle resistance.

Improves bending cycle life by distributing stress across fibers.

High-cycle cables must maintain electrical integrity throughout their lifespan.

Voltage Rating: Must meet or exceed system requirements to prevent insulation breakdown.

Current Carrying Capacity: Proper conductor sizing prevents overheating.

Signal Integrity: Shielding and twist control minimize EMI and crosstalk for data or control cables.

Capacitance and Resistance: Critical for long runs, particularly for high-speed data transmission.

Cables in high-cycle applications often operate in challenging environments.

High temperatures can soften insulation; low temperatures may make cables brittle.

Materials like polyurethane or rubber maintain performance across wider ranges.

Outdoor or industrial installations require chemical and water-resistant jackets.

Abrasion resistance reduces wear from friction on pulleys or guides.

Outdoor installations need UV-stabilized jackets to prevent cracking or discoloration.

Proper installation maximizes reel cable performance and lifespan:

Align Reel and Load Movement: Avoid twisting or uneven stress.

Maintain Minimum Bend Radius: Use appropriate reel diameter and guide rollers.

Avoid Excessive Tension: Adjust spring or motorized reels for smooth retraction.

Check Environmental Compatibility: Ensure cable materials match temperature, chemical, and moisture conditions.

Regular Inspections: Monitor for wear, cracks, or electrical degradation.

Routine maintenance prolongs cable life in high-cycle environments:

Visual Inspections: Check for fraying, cracks, or exposed conductors.

Cleaning: Remove dust, oils, or chemicals that can degrade the jacket.

Tension Adjustment: Ensure retraction mechanisms are functioning smoothly.

Electrical Testing: Periodically test insulation resistance and continuity.

High-cycle cables can develop predictable problems if design or installation is inadequate:

Conductor Fatigue: Caused by excessive bending or torsion.

Insulation Cracking: Often due to low-quality material or repeated sharp bends.

Outer Jacket Wear: Results from abrasion, chemical exposure, or UV degradation.

Connector Failure: Stress at termination points from poor strain relief or excessive pulling.

Addressing issues early reduces downtime and prevents costly replacements.

High-cycle reel cables vary in cost depending on materials, construction, and design features. Consider:

Long-term reliability: Investing in quality materials reduces maintenance and replacement costs.

Operational demands: Match cable strength and flexibility to actual cycle frequency and load.

Environmental conditions: Factor in exposure to chemicals, moisture, UV, and temperature.

A careful balance between cost and performance ensures safe, efficient operation.

Emerging innovations focus on durability, flexibility, and monitoring:

Smart cables: Embedded sensors for temperature, strain, and bending cycles.

Advanced polymers: Lightweight, abrasion-resistant jackets with extended bend life.

Eco-friendly materials: Recyclable, non-halogen insulation for sustainable solutions.

Enhanced shielding: Supports higher-speed data transmission in dynamic environments.

These trends improve both reliability and operational efficiency in high-cycle applications.

Reel cable design is a critical factor in high-cycle applications. Mechanical structure, material selection, insulation type, and reel mechanism all influence flexibility, durability, and electrical performance.

For optimal results, installers and engineers should consider:

Conductor and insulation quality

Outer jacket material and abrasion resistance

Torsion and bending tolerance

Environmental exposure

Proper reel alignment and tension management

Regular inspection and maintenance

By understanding and applying these design principles, reel cables can provide safe, reliable, and long-lasting performance even in the most demanding high-cycle applications.

این وب سایت از کوکی ها استفاده می کند تا اطمینان حاصل شود که بهترین تجربه را در وب سایت ما به دست می آورید.

اظهار نظر

(0)